SOLUTIONS FOR WIND TOWER LIGHTING:

MEETING THE HIGHEST STANDARDS WITH PLUG & PLAY

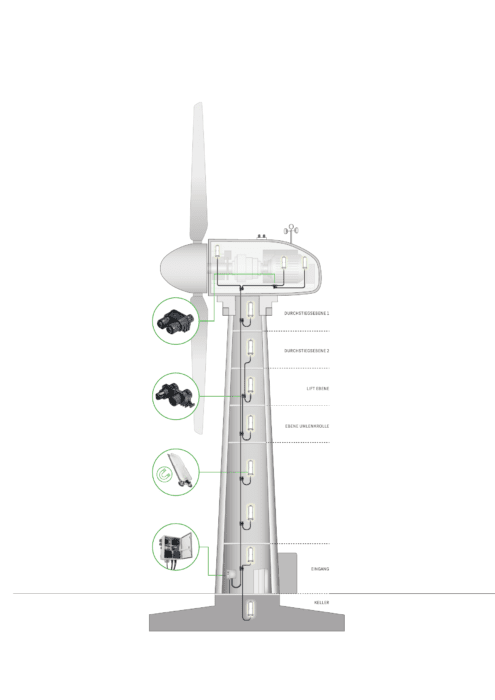

Short planning times and maximum availability of the lighting in the tower and nacelle – Wieland Electric knows how to meet these requirements for wind turbines. Pluggable and centrally supplied power distribution and lighting systems can shorten project planning times and accelerate the installation and approval of wind towers.

Starting with the infrastructure cabling inside wind turbines, the podis® power bus system provides the necessary backbone for all wind turbine power connections. This impressive power distribution system is based on a TC-ER cable that provides up to 60 A of power over long distances. With 80% faster installation than traditional pipe-and-wire and reduced waste, this system makes it easy to quickly scale a project to multiple towers.

The pluggable RST® round cable system, with worldwide international approvals, ensures maximum flexibility in infrastructure cabling. Whether lighting, maintenance sockets, or control cabinets – all components are quickly, safely, and correctly plugged together in the factory or on-site. This reduces installation time by as much as seventy percent (70%).

For reliable standard and emergency lighting in the tower, Wieland Electric has robust and low-maintenance LED lights available, which can be mounted easily, quickly, and efficiently according to the plug & play principle. Tools-free mounting is possible using quick mounting plates on the cable tray (wire tray) or, in steel towers, directly to the tower wall using magnets. In the event of a power failure, a battery-backed uninterruptible power supply (wipos® UPS) provides power for the lighting and ensures a safe descent for personnel.

In addition, the Wieland Electric system consisting of cable trees, connectors, LED lights, and UPS is ideal for retrofitting. As a pluggable all-in-one solution, it supports a standard-compliant retrofit of task and safety lighting without having to remove any legacy hardware. The centrally supplied safety lighting system, which is based on a secondary voltage of 48 V DC (SELF) or normal mains voltage of 230 V AC, enables at least 30 minutes of buffering after a power failure.

For maximum reliability, Wieland Electric also offers simulation of the proposed wind tower lighting solution. Our software-based simulation takes into account all aspects of the design, components, and installation for the lighting application in the tower. Planning the lighting concept under real conditions significantly accelerates the ordering and approval process for our wind turbine customers.